Marijuana

Role of Quality Assurance in Cannabis Sales

Roughly eighty percent of Canadian consumers cite product safety as their top concern when buying cannabis online. For dispensary owners and quality assurance professionals across North America, maintaining strict safety protocols has become a non-negotiable demand. As regulations tighten and consumers demand greater transparency, understanding how quality assurance protects both your brand and buyer confidence is now central to long-term success.

Table of Contents

- Defining Quality Assurance In Cannabis

- Key Quality Standards And Processes

- Legal Compliance And Industry Regulations

- The Quality Assurance Person’s Responsibilities

- Risks, Audits, And Common Pitfalls

Key Takeaways

| Point | Details |

|---|---|

| Quality Assurance Importance | A comprehensive quality assurance framework ensures product safety, consistency, and compliance throughout the cannabis supply chain. |

| Role of Quality Assurance Professionals | Quality Assurance Professionals are essential for maintaining rigorous standards and ensuring compliance with evolving regulations. |

| Regulatory Compliance Challenges | Cannabis businesses must navigate complex legal landscapes that require constant monitoring and adaptation to maintain compliance. |

| Risk Management Strategies | Businesses should implement robust risk management strategies that address operational vulnerabilities and ensure ongoing regulatory adherence. |

Defining Quality Assurance in Cannabis

Quality assurance in cannabis represents a comprehensive framework of systematic processes designed to guarantee product safety, consistency, and regulatory compliance throughout the entire supply chain. Unlike traditional quality control methods, cannabis quality assurance integrates rigorous scientific testing, regulatory standards, and consumer protection protocols.

At its core, quality assurance encompasses comprehensive testing methodologies that evaluate multiple dimensions of cannabis products. These evaluations include chemical composition analysis, screening for potential contaminants, verifying potency levels, and ensuring products meet stringent health and safety standards. Specifically, quality assurance processes examine critical factors such as:

- Pesticide residue levels

- Microbial contamination

- Heavy metal content

- Cannabinoid concentration

- Terpene profile consistency

Quality assurance extends beyond laboratory testing, integrating complex regulatory frameworks that monitor product integrity from cultivation through final sale. This holistic approach not only protects consumer health but also helps eliminate potential criminal influences within the cannabis supply chain. By establishing transparent, scientifically validated protocols, quality assurance transforms cannabis from an unregulated commodity into a professionally managed, safety-driven industry.

Pro Tip: Quality Documentation: Maintain meticulous batch testing records and certificates of analysis for each cannabis product, ensuring full traceability and rapid recall capabilities if any quality concerns emerge.

Key Quality Standards and Processes

Quality standards in the cannabis industry represent a sophisticated framework of scientifically validated protocols designed to ensure product integrity, safety, and consistent consumer experience. These standards transcend simple testing procedures, encompassing comprehensive guidelines that govern every stage of cannabis production and distribution.

Global harmonization efforts have emerged as a critical component in establishing rigorous cannabis quality benchmarks. These international collaborations, such as the USP-ASTM framework, focus on creating standardized criteria that address multiple critical dimensions:

- Precise cultivation practices

- Standardized manufacturing protocols

- Comprehensive laboratory testing methodologies

- Consistent distribution guidelines

- Transparent product labelling requirements

The implementation of these quality standards involves intricate cross-jurisdictional compliance strategies that prioritize consumer protection and industry credibility. By establishing measurable, repeatable processes, these standards transform cannabis from an inconsistent product into a professionally managed, scientifically validated commodity. This approach not only mitigates potential health risks but also builds robust consumer trust through transparent, rigorous quality control mechanisms.

Pro Tip: Standard Implementation: Develop a comprehensive internal quality management system that continuously tracks and documents compliance with current cannabis quality standards, ensuring your processes remain adaptable to evolving regulatory landscapes.

Legal Compliance and Industry Regulations

Legal compliance in the cannabis industry represents an intricate landscape of evolving regulations that demand constant vigilance and strategic adaptation. As jurisdictions worldwide continue to reshape their approach to cannabis, businesses must navigate a complex web of national and international legal frameworks that vary dramatically across different regions.

Global cannabis regulations demonstrate significant complexity, with key considerations including:

- Permit and licensing requirements

- Cultivation quantity restrictions

- Distribution channel controls

- Advertising and marketing limitations

- Product testing and documentation standards

The international legal context remains particularly nuanced, with regulatory models continually contested between strict prohibition and progressive legalization approaches. Businesses must remain agile, understanding that legal compliance extends beyond simple rule-following to proactively managing potential regulatory shifts. This requires comprehensive monitoring of legislative changes, maintaining robust documentation, and developing flexible operational strategies that can quickly adapt to emerging legal requirements.

The following table summarizes how quality assurance, quality control, and legal compliance interact within the Canadian cannabis industry:

| Aspect | Quality Assurance | Quality Control | Legal Compliance |

|---|---|---|---|

| Main Focus | Preventing defects and issues proactively | Identifying and correcting issues post-production | Meeting statutory and regulatory requirements |

| Key Activities | Establishing protocols, continuous monitoring | Product testing, batch analysis | Licence management, documentation |

| Outcome for Business | Consistent product standards, consumer trust | Reduction of faulty goods, recall minimisation | Reduced legal risk, market access |

Pro Tip: Regulatory Intelligence: Establish a dedicated compliance team or consultant who specializes in tracking cannabis regulatory developments across relevant jurisdictions, ensuring your business remains ahead of potential legal modifications.

The Quality Assurance Person’s Responsibilities

Quality Assurance Professionals serve as the critical guardians of product integrity and safety in the cannabis industry, occupying a pivotal role that bridges scientific precision, regulatory compliance, and operational excellence. Their responsibilities extend far beyond simple quality checks, representing a comprehensive approach to maintaining the highest standards throughout the entire production ecosystem.

Quality Assurance Persons (QAPs) manage an intricate network of quality control protocols that encompass multiple critical dimensions:

- Developing and approving comprehensive Standard Operating Procedures (SOPs)

- Conducting rigorous internal audits

- Managing detailed record-keeping systems

- Investigating and resolving product complaints

- Ensuring consistent regulatory compliance

- Implementing continuous improvement strategies

Their role demands exceptional technical expertise and proactive risk management, requiring a multifaceted skill set that combines scientific knowledge, regulatory understanding, and strategic problem-solving capabilities. QAPs must continuously adapt to evolving industry standards, anticipate potential quality risks, and develop robust mitigation strategies that protect both consumer safety and organisational reputation. This requires a dynamic approach that balances meticulous attention to detail with broad systemic thinking.

Below is a reference table outlining essential professional qualities for a Quality Assurance Person (QAP) in cannabis manufacturing:

| Attribute | Description | Industry Benefit |

|---|---|---|

| Analytical Expertise | Ability to interpret complex lab data | Accurate defect identification |

| Regulatory Knowledge | Up-to-date on legal and quality standards | Fewer compliance breaches |

| Leadership Skills | Guides teams in SOP adherence | Improved process consistency |

| Problem Solving | Rapidly addresses emerging issues | Minimises operational downtime |

Pro Tip: Continuous Learning: Develop a personal professional development plan that includes regular training in emerging cannabis regulations, analytical technologies, and quality management methodologies to stay ahead of industry shifts.

Risks, Audits, and Common Pitfalls

Risk management in the cannabis industry represents a complex challenge that demands comprehensive strategic approaches, combining meticulous compliance protocols with proactive operational safeguards. The regulatory landscape remains exceptionally dynamic, requiring businesses to maintain constant vigilance and adaptability in their quality assurance practices.

Internal audit teams must concentrate on critical risk areas that encompass multiple critical dimensions:

- Legal and regulatory compliance gaps

- Financial control vulnerabilities

- Operational process inconsistencies

- Technology infrastructure weaknesses

- Documentation and record-keeping standards

Cannabis enterprises face particularly nuanced compliance challenges, including complex financial transactions, fragmented regulatory requirements, and persistent operational uncertainties. These challenges demand robust frameworks that can rapidly adapt to evolving legal landscapes while maintaining rigorous quality standards. Successful risk mitigation requires a holistic approach that integrates continuous monitoring, comprehensive documentation, and proactive strategic planning to anticipate and address potential vulnerabilities before they escalate.

Pro Tip: Risk Documentation: Create a dynamic risk registry that tracks potential compliance issues, assigns clear ownership for mitigation strategies, and includes regular review cycles to ensure ongoing operational resilience.

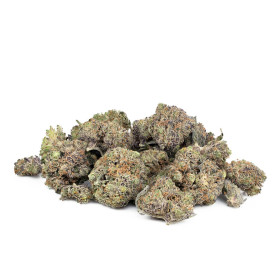

Elevate Your Cannabis Experience with Trusted Quality Assurance

Navigating the complexities of cannabis quality assurance and legal compliance can feel overwhelming. Ensuring every product is safe, consistent, and meets rigorous standards is critical for your health and satisfaction. At GreenSociety.cc, we understand the importance of scientifically validated quality control and transparent documentation that aligns with industry protocols. Our platform is designed to deliver peace of mind by offering a wide selection of products backed by thorough batch testing and regulatory diligence.

Discover the difference that professional quality assurance makes in your cannabis purchase. Explore our curated range of flowers, edibles, concentrates, and more, all available for convenient and discreet online ordering at GreenSociety.cc. Stay informed with our educational resources and shop confidently knowing that each product adheres to the highest standards. Visit GreenSociety.cc today and experience seamless cannabis shopping with a commitment to safety and excellence.

Ready for a reliable cannabis source? Start browsing now at GreenSociety.cc and transform your cannabis journey with quality you can trust.

Frequently Asked Questions

What is the role of quality assurance in the cannabis industry?

Quality assurance in cannabis serves to ensure product safety, consistency, and compliance with regulatory standards throughout the supply chain. It involves systematic testing and protocols to safeguard consumer health and build trust in the industry.

How does quality assurance differ from quality control in cannabis sales?

Quality assurance focuses on preventing defects and ensuring product integrity proactively, while quality control addresses any issues post-production through testing and corrections. Quality assurance is more about establishing standards, whereas quality control is about verifying adherence to those standards.

What are the key components of quality assurance in cannabis products?

Key components of quality assurance include comprehensive testing for pesticide residues, microbial contamination, heavy metals, cannabinoid concentrations, and maintaining consistency in terpene profiles. These elements help confirm that products meet safety and health standards.

Why is regulatory compliance important in cannabis quality assurance?

Regulatory compliance is crucial for cannabis quality assurance as it reflects adherence to legal standards governing production, distribution, and marketing. Ensuring compliance reduces legal risks, fosters consumer trust, and supports a transparent, safe market for cannabis products.

Recommended

- Cannabis Quality Assurance: Complete Consumer Guide ~ Green Society Blog

- Understanding Why Product Quality Matters for Cannabis ~ Green Society Blog

- Understanding What is Cannabis Traceability and Why It Matters ~ Green Society Blog

- Understanding Why Third-Party Testing Matters for Cannabis ~ Green Society Blog